Successful robotic welding solutions depend on quality fixtures

High quality products begin with high quality components, held in place by precision engineered fixturing.

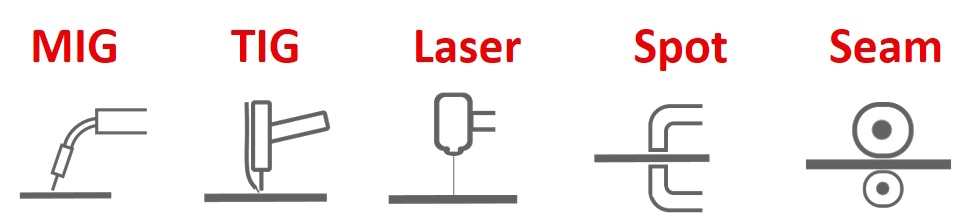

At ICS, we have many years of experience, designing and manufacturing fixtures for MIG, TIG, Spot and Laser welding. We’ve produced simple cost-effective manual fixtures for batch production, fully automated high-volume fixtures that are engineered to the most demanding automotive standards, and everything in-between.

Our in-house fixture design and manufacturing facility puts us in a unique position. Backed by our full robotics and automation systems build capabilities, plus our technical and applications support services, we provide you with a full turnkey robotics welding solution from a single source.

We understand the complexities of fixture design, to meet both the specific requirements of often complex part construction, and the capabilities and limitations of particular laser and robotic systems. This means that every fixture we produce is right first time, every time.

Designed in house

Starting with your drawings, 3D CAD models or physical samples, our in-house design team develop a concept that meets your exact needs. Once finalised, our expert designers transform the concept into a world-class design. Digital prototyping completes the design process, including mechanical analyses and robot movement simulation, where welding torch access and cycle times are verified. This ensures that the accuracy and function of each fixture is proven at the design stage.

Built in house

Engineered in our workshop and customised to match your final components, each fixture is quality approved, including dimensional verification by our advanced coordinate measurement (CMM) system. Fixtures can be supplied as stand-alone units or integrated into one of welding cells to give you an outstanding turnkey automated welding solution.

Do you have a robot preference?

We have in depth experience across all makes of robots including Panasonic, KUKA, ABB, Fanuc, Kawasaki and Yaskawa. If you already have an established robot partner, we have the capabilities to work with your chosen manufacturer but given the choice we will recommend Panasonic for Mig and Tig robotic welding applications.

Learn MoreRobot welding solutions to suit your need

We can offer a wide range of options from a flexible stand-alone welding cell from our standard range to a fully bespoke welding process line including component fixturing and handling for products that include multiple welds of differing types. If you are looking to improve your production, we will work with you to find the best robotic welding solution to meet your needs.

Standard Cell for MIG & TIG Welding

The ProCell range is a SMART (Standard Modular Advanced Robotic Technology) answer to your robotic welding needs. Using the latest Panasonic TAWERS welding technology, this flexible cell has been designed to produce faster cycle times and higher quality welding, be easier to operate and offer lower cycle costs.

Bespoke Welding Solutions

If you have a more complex welding process or larger components to weld, then you may require a bespoke solution. This is where we really excel by applying some creative thinking backed by our in-depth engineering and robotic welding experience to provide a solution to overcome your particular production challenges.

Laser Welding Solutions

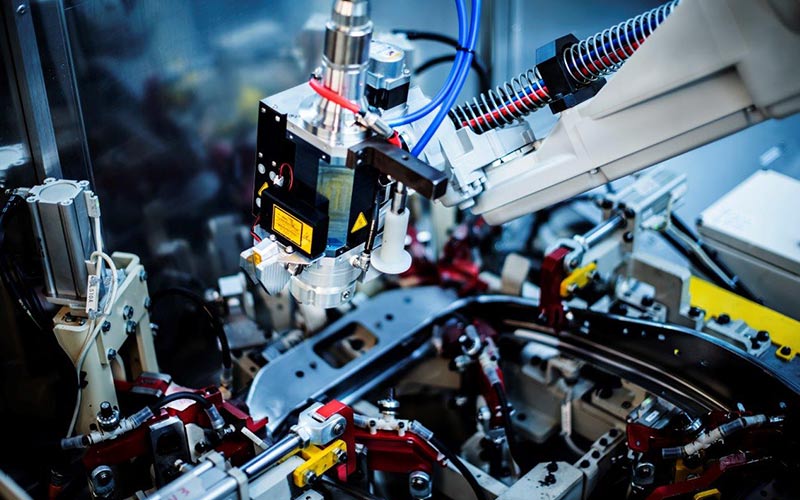

Laser welding offers many benefits including higher precision, increased speed and high productivity. ICS has completed many successful laser welding projects for customers, giving them a direct and substantial competitive edge and helping them to win new types of work.

Robotic Welding Fixtures

Reliable and stable jigs and fixtures are essential to ensure repeatability and quality welds. Our in-house team have the experience to design all types of fixtures from simple manual clamping solutions through to complex automatic fixtures to cope with the high demands of laser welding or automotive and aerospace industries.