The Manufacturing Technology Centre (MTC) was established in 2010 as an independent Research & Technology Organisation with the objective of bridging the gap between academia and industry.

The MTC provide integrated manufacturing system solutions for customers large and small, across sectors as diverse as automotive, aerospace, rail, informatics, food & drink, construction/civil engineering, electronics, oil & gas and defence.

The Manufacturing Technology Centre (mtc) in association with innovate UK, had the requirement for the design and manufacture of a robotic demonstration cell. Within this cell the mtc plan to develop non-destructive testing techniques for rapid prototype components. Our role in the project was to provide a robot demonstration cell that the mtc could use to develop their process.

Phillip Jackson a Technical Specialist from the MTC came to ICS with a simple brief:

“We need a robot cell, and we need it quick”

Recognizing the urgency, ICS were able to gather the relevant information rapidly proposing a high value solution with a swift delivery timescale; from the point of initial conversation ICS had planned, concepted, and costed the project in less than a week.

Given the green light by the mtc procurement department, ICS went on to fit the project into an already busy schedule. ICS working with close communication with the mtc, designed all electrical, mechanical and safety aspects of the system which flew though design sign off with no queries

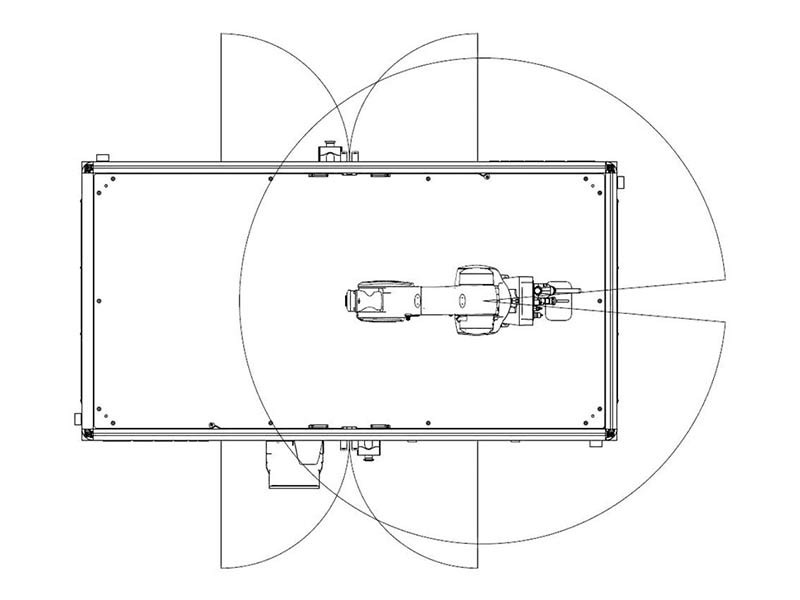

Small Demonstration Cell

The system was based around a Kuka KR6 R900 Six Axis Kinematic Robot free Issued by the MTC along with a KRC4 Kuka Robot controller. The upper portion of the cell is guarded with aluminum extrusion and polycarbonate sheet safeguarding the robot. The lower section of the system houses all electrical equipment and additional guarding including the KRC4 Robot controller. ICS received delivery of the Robot and installed it within the frame performing a full commission testing of all its basic functionality.

"The cell has been met with universal praise and appreciation for the quality of construction. I understand the project consortium are very happy with it too. "

- Philip Jackson - Technical Specialist MTC