Accessibility Controls

The player supports TAB to change the controls.

Update Required

To play the media you will need to either update your browser to a recent version or update your Flash plugin.

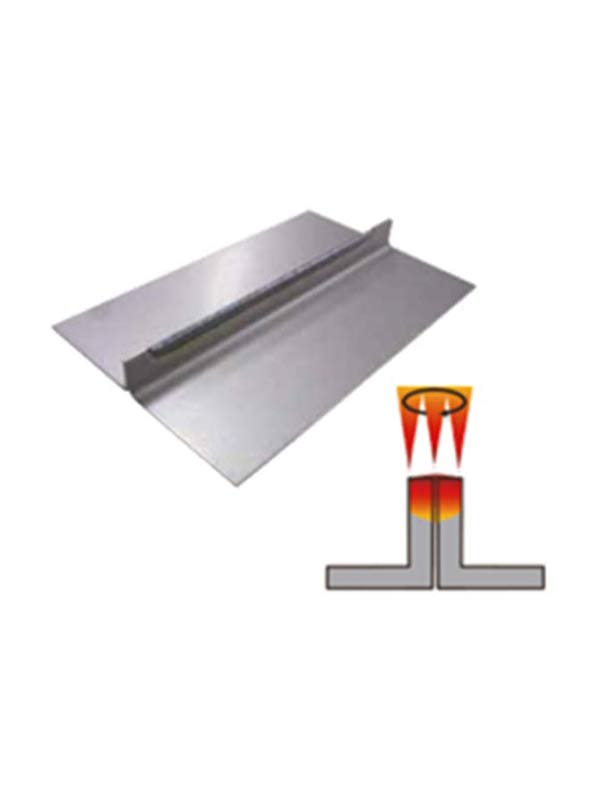

Laser Processing Robot Integrated System Solution (LAPRISS)

LAPRISS uses Panasonic servo control technology to control a laser trepanning head to generate several welding pattern and beam functions. This technological advantage makes the laser head extremely compact and light weight with a payload weight of only 4.5kg.

An advantage of this low weight is to allow the laser head to be mounted to the high speed compact Panasonic TM series of robots.

The result is a complete system with unique compactness and a seamless interface between the process and automation components.

The 4kW Direct Diode Laser offers high energy density for low heat input welding with lower running costs than traditional YAG laser systems.

All components are controlled by the same teach pendant with easy programming using laser navigation software.

The Trepanning Laser Head can produce weld patterns without robot movement.

Welding with the laser spinning process from Panasonic allows you to reduce cycle times, prevent undercut at high penetration depths as well as achieve very good gap bridging and very low thermal distortion.

New joint configurations can be used to replace arc welding