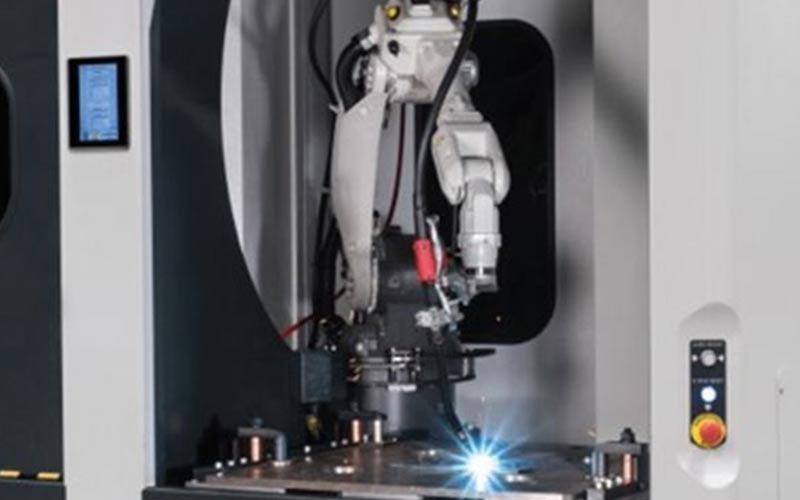

ProCell W is a range of SMART welding robot systems

The ProCell W range is SMART because it has been designed using Standard Modular Advanced Robotic Technology. The latest Panasonic TAWERS welding technology and 30+ years of automated welding experience encapsulated in one flexible solution. The ability to quickly and effortlessly reconfigure component fixtures and allow for repurposing for future projects has been key to the ProCell's popularity.

ProCell W Range - Seven simple solutions

Each robot cell will offer you the following benefits:

Flexibility

Many options are available for fixture location, control and component manipulation. The robot and power source is capable of MIG, MAG and TIG welding on mild steel, stainless steel, galvanised steel, aluminium and others. Thin and thick plate welding can be performed using the same system.

Standard Features

- Base-mounted for quick installation and easy relocation

- Plug and play operation with a single power drop

- Built-in fume hood

- Automatic open and close doors with integral safety

- Intuitive touch screen controls

- Operator prompts and error resolution on screen

- All controls positioned at front of cell

Optional Extras

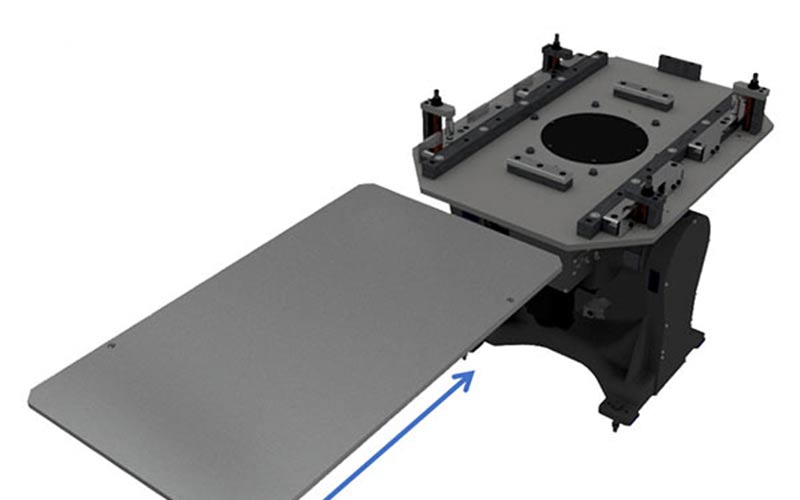

- Dynamic tilt & turn tooling table

- Remote diagnostics and support

- Industry 4.0 compatible

- Multiple options for fixture rotation

- Upgrades for fixture control