Handling Solutions

Robots of all sizes can be used in handling applications. They provide speed, precision, high load carrying capacity, tireless performance and repeatability, offering possibilities for cost saving and other benefits in your production operation.

We can integrate vision to our robots to enable random position picking, orientation control, individual part identification, part inspection and other opportunities to improve your process.

Detailed below are just a few of the ways in which we have integrated handling and loading robots into our system solutions.

Whilst maintaining our ethos of being an independent system integrator ICS are a Gold solutions provider for the extensive range of KUKA Robots.

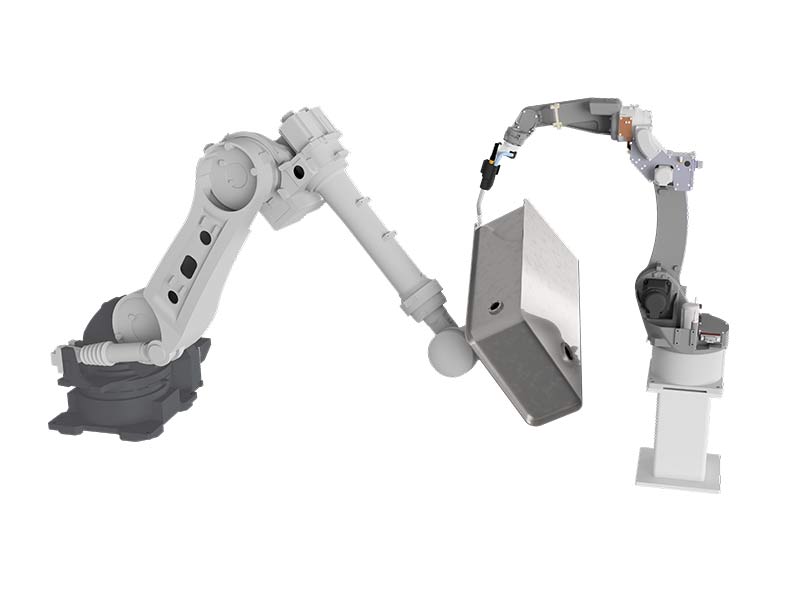

Fixtureless Welding

Utilising the high-speed communication between robots we can harmonise their movements allowing a handling robot to position and move a tacked component in front of a welding robot to provide true fixture-free welding. Both robots can be manipulated individually or concurrently and can incorporate touch or laser position sensing and through-arc seam tracking, for perfect welds every time.

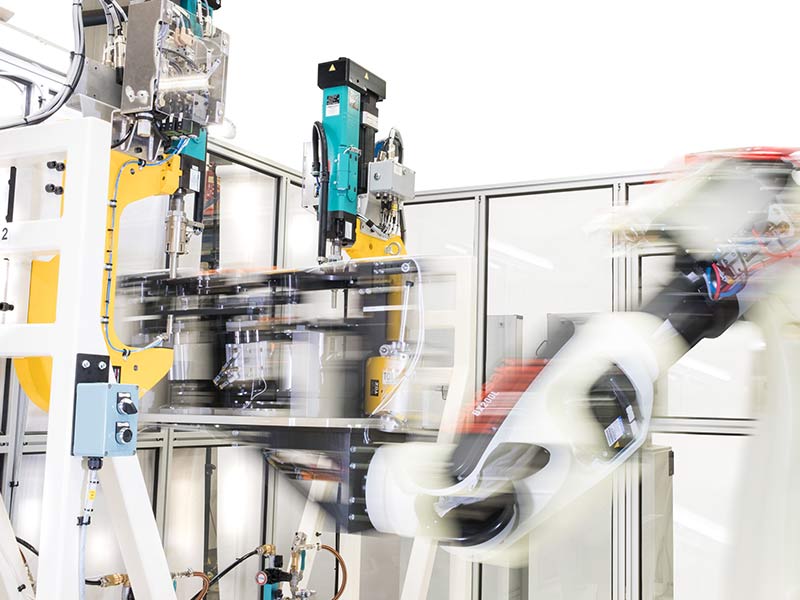

Handling multiple processes with the same robot

This system uses large handling robots to pick-up fixtures and take them to the production process. The system integrates spot welding, seam welding and MIG welding processes on the same product, with each component being tested by the robot before being placed on a conveyor to the next process.

Product Handling

A robot is used to unload an air under water leak test machine (designed and manufactured by ICS). The product is taken to a marking machine and then unloaded to the next process. Innovative guarding allows the machine to be configured to right hand, left hand or straight through operation.

You can learn more about our Handling Automation capabilities here

Learn More

We can offer many years of experience to develop a solution to suit your needs and budgets

Get in touch to see how we can help you.