We help you solve your production challenges

We live in a fast-changing world, where keeping ahead of the competition demands constant innovation and improvement. That’s where we come in, helping you build the vital competitive edge that means the difference between success and failure.

We have specialised in engineering robotics and automation systems since 1989. Today, we are backed by a global automation giant, AWL, and provide a total turnkey service.

We partner with customers throughout industry, from automotive, agricultural and medical to general manufacturing. Our product experience is extensive and includes: car seats, exhausts, radiators, chassis, excavators, furniture, aircraft engine parts, building products and control cabinets.

Throughout, our goal is to help each customer improve key business factors such as productivity and quality, and to empower them to win more profitable business by introducing flexible robotic and automation solutions.

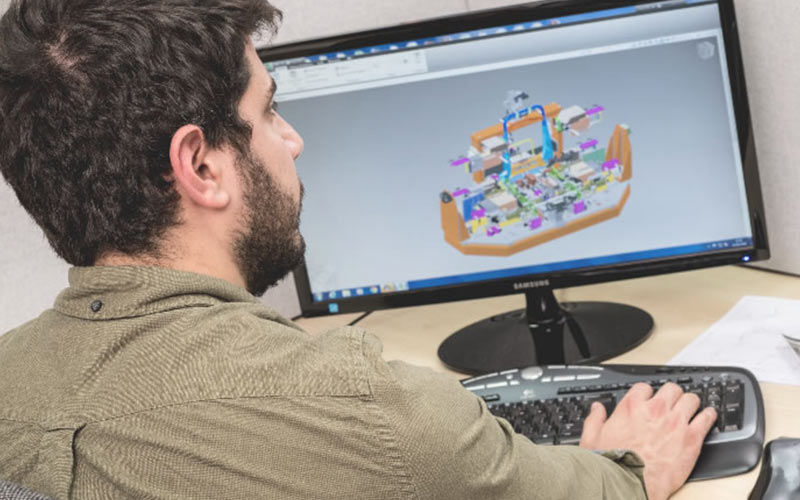

We take the time fully to understand your production processes. We can advise on the most appropriate robotics solution – or indeed, if a robot is the best option. We then work with you as an extension of your engineering team to develop a robotics system that adds real value to your business.

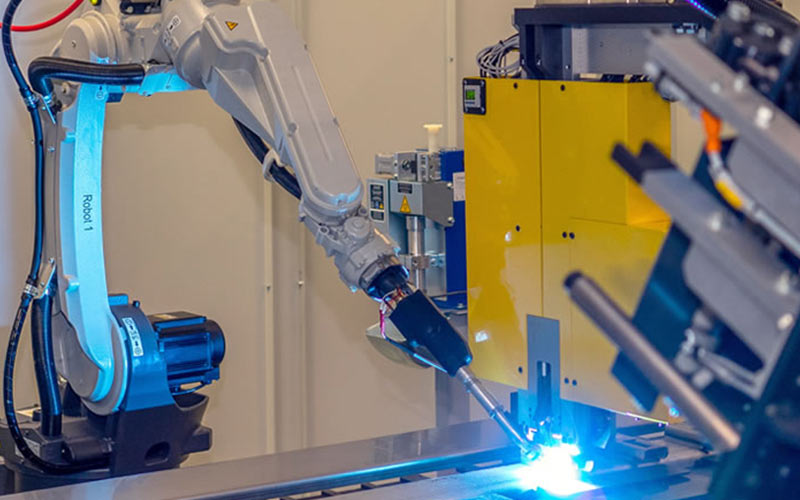

Robotic welding systems

We deliver fully integrated robotic welding systems, partnering with you and your team, to identify the challenges and then custom engineering robotics systems that meet your exact requirements - on time and within budget. Our innovative approach, combined with smart, flexible, intuitive robotics technologies ensures you stay firmly ahead of your competition.

Robotic handling solutions

We guarantee higher productivity for you, through smart and reliable robotics handling solutions, backed by over 30 years of automation experience. We combine the latest technologies in robotics and vision to give you a vital competitive edge.

System re-engineering

Robots, if maintained correctly, have a long operating life. If your production process or product has changed then we can re-engineer a new robot system for you based around your used robot and other key components.

Component fixturing

At the heart of every robot welding system is the jig or fixture. Accurate fixturing is essential for high and constant weld quality. Innovative fixture design will facilitate easy torch access, reduce cycle times and is the key to achieving consistent quality and reduced production costs.